ELA Innovation and IER Bolloré streamline the Renault group’s equipment flows

Who They Are

A French multinational automobile manufacturer, Renaut needed to optimize the management of its packaging chain. ELA Innovation and IER Bolloré have enabled Renault to optimize the management of its packaging line thanks to a bi-technological indoor location solution (“DOT” Active RFID and Passive RFID). ELA Innovation brought its expertise in Active DOT RFID technology, to locate, detect and historize the movements of all the logistic equipment. Thanks to the latter, operators gain in time, make packaging inventories more reliable and obtain better real-time tracking statistics.

As integrator of the solution, IER Bolloré provided the means of capturing location information. ELA Innovation provided the necessary tags for locating equipment.

Client Needs

- Locate, detect and log all froklift movements

- Calculate the travel time of the packages in the warehouse

- Optimize the packaging chain

The Equipment

- Actif RFID Tags: PUCK DOT1

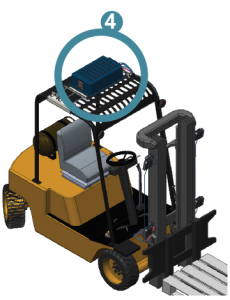

- Tag Activator2 positioned in the housing4 of the forklift truck

- RFID3 reader (Sciel Reader IP2) positioned in the housing4 of the forklift truck

We appreciated the ease of installation and integration of the ELA tags thanks to their mounting brackets, which allow us to quickly readjust the area as needed.

Luc Filizzola – Digital project manager – Renault

The Operate Mode

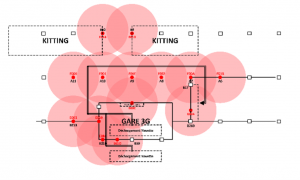

From a technical point of view, the solution is based on a set of Active RFID PUCK DOT and Tag Activator.

The Tag Activator attached to the logistic equipment, activates the PUCK DOT positioned at regular intervals in the warehouse when it enters the field of the latter. The activated PUCK DOT then captures the magnetic field generated by the Tag Activator and sends its identifier and that of the Tag to the IoT platform.

This solution makes it possible to locate the forklift truck in the warehouse and record its movements. The tag makes it possible to know the departure and arrival points of the logistic equipment and thus to calculate its travel time. This creates a great possibility to optimize and automate inventories.

This solution makes it possible to locate the forklift truck in the warehouse and record its movements. The tag makes it possible to know the departure and arrival points of the logistic equipment and thus to calculate its travel time. This creates a great possibility to optimize and automate inventories.

The Advantages

- Easy to deploy solution

- Real-time data feedback

- Environmentally scalable infrastructure

- Compliance with health standards for operators

- Long tag’s battery life

The Results

- Improvement in inventories accuracy

- Optimization of the packaging line